Silica is a common mineral found in sand, stone, and concrete. Because of where it is found, silica dust exposure often occurs when cutting, sawing, grinding, drilling, or crushing stone. It can also be released during abrasive blasting and other common practices on construction sites.

Most people don’t know that silica is 100 times smaller than a grain of sand, so people, particularly construction workers, breathe it in without even knowing it. In fact, it’s estimated that 2.3 million people in the United States are exposed to silica at work, often via inhalation.

In this article, we’ll discuss the impact silica has on human health and why silica training (particularly for construction workers) is crucial.

The Health Hazards of Respirable Silica Exposure

Workers in construction, mining, manufacturing, oil and gas extraction, and agriculture are at a higher risk for silica exposure, and prolonged exposure can lead to several long-term health hazards, including:

- Lung Cancer: Long-term or repeat exposure to silica dust can significantly increase the risk of developing lung cancer. When inhaled, silica particles can embed into lung tissue, leading to scarring that may cause tumors.

- Silicosis: Silicosis is an irreversible lung disease that can occur quickly following silica exposure. This condition makes it difficult for the lungs to bring in oxygen, so symptoms typically include breathing difficulties.

- COPD: Chronic obstructive pulmonary disease or COPD, involves shortness of breath, emphysema, and chronic bronchitis, and tends to worsen over time.

- Kidney Disease: The tiny silica particles cause inflammation in the body, which, over time, affects not only the lungs but also the kidneys. This inflammation (and potential scarring) means that the kidneys will start to lose their ability to filter waste from the blood.

OSHA Standards for Silica

One way to reduce silica exposure is to develop stringent policies and guidelines within your workplace. Your guidelines should enforce OSHA’s two silica standards:

- 1926.1153: This standard only applies to construction environments, and defines acceptable exposure for workers as 25 micrograms per cubic meter of air per 8 hours.

- 1910.1053: This silica standard applies to other settings outside construction and certain agricultural operations. This particular standard sets a permissible exposure limit (PEL) of 50 micrograms per cubic meter of air per 8 hours. Applicable employees must be properly notified of the standard and trained on it. Medical surveillance must also be provided for applicable employees. If workers operate in areas that exceed the defined PEL, respirators must be provided to keep workers safe.

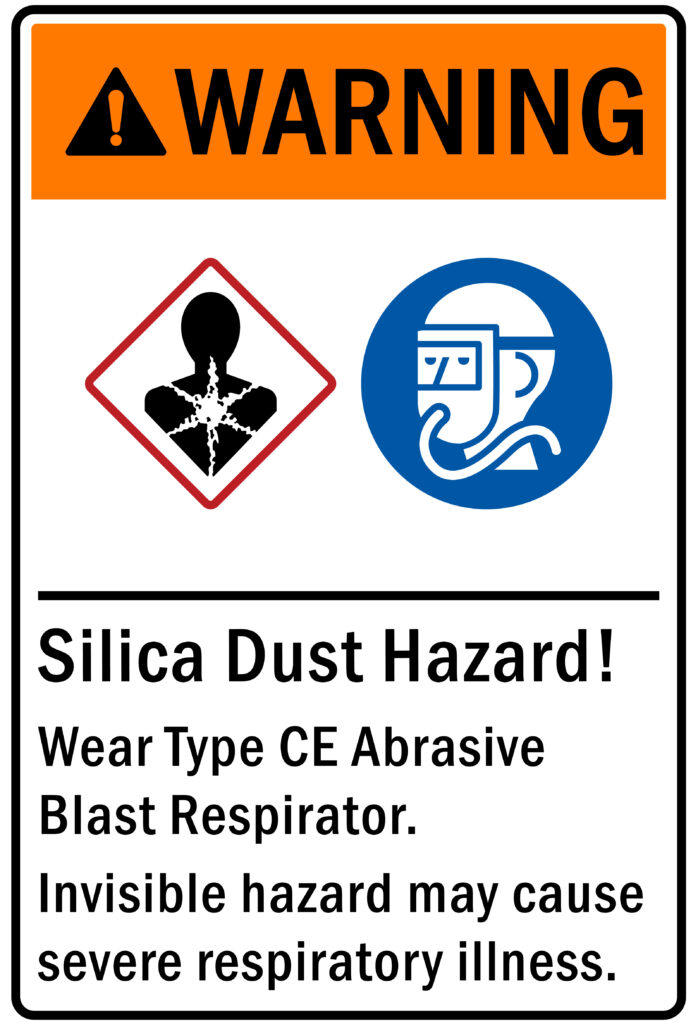

Three ways that businesses can remain compliant with OSHA standards is by 1) ensuring workers have N95 respirators that fit properly 2) assessing the air quality with silica dust monitoring devices when needed, 3) scheduling silica-focused training.

What Silica Training Covers

Silica training courses, such as the ones offered by Archview Services, combine practical exercises and classroom learning, culminating with a final exam and Competent Person Certification upon passing. Our courses are designed to cover preparation for working with silica during activities that pose a higher exposure risk, like construction. No prior certification or experience is necessary to enroll in these courses.

Key lessons include:

- Understanding what silica is (and its health hazards).

- Identifying signs of silica in the workplace.

- Familiarizing students with standard OSHA regulations for silica protection.

- Creating exposure control plans for silica dust.

- Identifying adequate control systems and safe work practices, such as using wet-cutting systems or vacuums with proper filtration

- Highlighting proper recordkeeping practices.

- Fitting and using respirators.

- Using monitoring devices to decrease the risk of silica exposure.

Minimize Risk & Schedule Silica Training Today

Archview Services is here to help you keep your workers safe. We offer on-site, year-round individual or group training and OSHA safety compliance assessments to businesses throughout the Midwest, including Missouri, Illinois, Kansas, Iowa, Nebraska, Arkansas, and Oklahoma. You can also lease or purchase safety equipment and monitoring devices from us, including the Trolex Air X series, a real-time dust monitoring system designed to help minimize silica exposure and respirators.

Call (314) 998-4505 today to learn more about our training program or to schedule a session for your employees.